- Store

- >

- Pick and Place (PnP)

- >

- Pick and Place head - dual nozzle - OpenPnP compatible

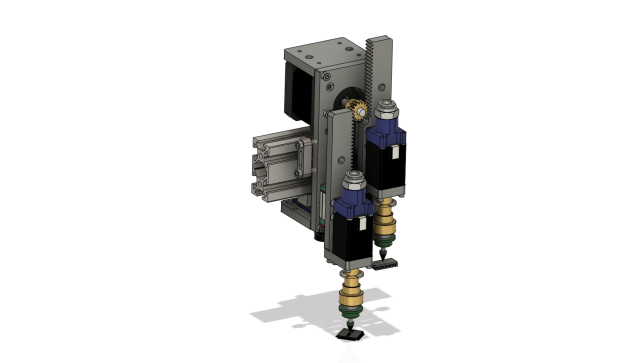

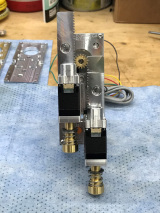

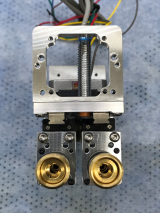

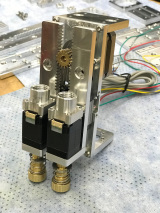

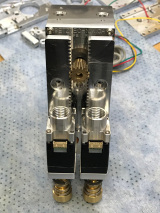

Pick and Place head - dual nozzle - OpenPnP compatible

OUT OF STOCK 2023-04-05. Waiting to schedule machining new kits...

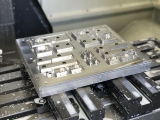

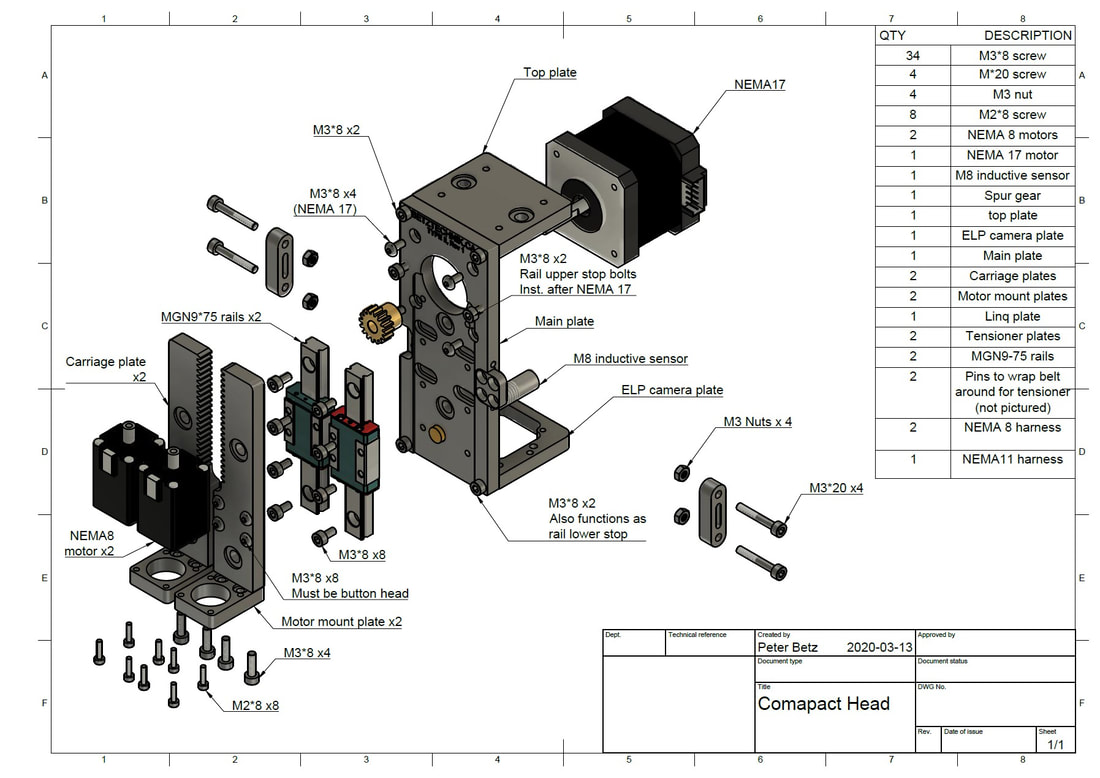

Dual nozzle head for pick and place machines. REFER TO THE LISTS BELOW FOR WHAT IS INCLUDED. Surface finish subject to change.

FULL KIT:

Full set of CNC MACHINED PLATES, Hardware, 2x high quality linear rails, 2x NEMA 8 hollow shaft motors, 1x NEMA 17 Z rotation motor, motor harnesses, inductive sensor, brass spur gear, 1/8" pins for locking the X axis belt in the tensioners.

PLATE AND SPUR GEAR KIT:

Includes all of the machined plates (9 including the two tensioner brackets) and the required spur gear. You will need to order the rails, motors, inductive sensor and hardware. See below for a list of the required parts to build the head (with buying references!).

(NEW!!) PLATE, SPUR GEAR AND HARDWARE KIT:

Includes everything in the Plate and Spur Gear Kit, as well as all the hardware (screws/ nuts/ pins) needed to assemble the head. Does not include components like the inductive sensor etc.

Links for options info:

Quick change Juki nozzle holders- NEMA8/ 11 hollow shaft

Machined NEMA 8 vacuum adapters

-

About

-

Setup/ homing

-

Downloads

-

BOM

-

Drawing

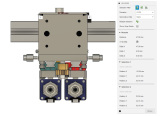

Mounts on a MGN 12H (long) or MGN 12C (short) rail bearing block for single head installation. You can chain heads together (see images below) using the Linq plate (supplied if you order 2 or more heads) and you can either use 2x 12C (short) bearing blocks (one on each head) or bridge 2 heads together using a single 12H (long block). Single head requires 3 stepper drivers (so a typical 5 axis control board will work on a machine that uses 1 X motor, and 1 Y motor), or a total of 8 stepper drivers for a dual head setup that uses 1 X and 1 Y motor (2x 4 axis control boards).

All mechanical parts are the same so upgrading from the old style to new style just requires a plate kit (and the required hardware)!!

Specifications:

- designed to mount to a standard 12mm linear rail (HIWIN with LONG block for example: MGN12H, Short block MGN12C).

Check out the head mounting drawing below for more details.

- 5mm hollow shaft for nozzle holder mounting.

- Each nozzle can drop down approximately 22.5mm from neutral.

- Homing is accomplished using an inductive sensor. See the homing tab for more details.

- Easy to modify the mounting plate for other systems (like openbuilds C beam, etc.)

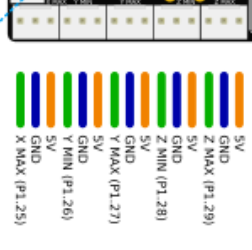

Wiring the inductive sensor

Configuring Smoothie

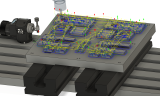

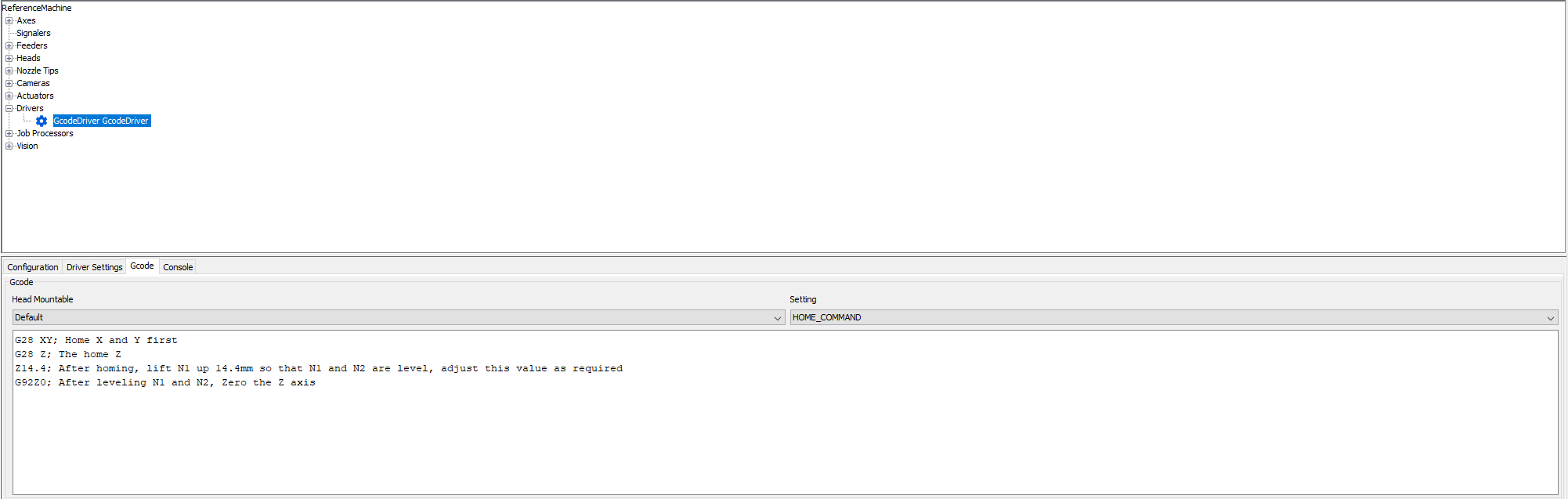

openPnP configuration

WARNING!

|

EXAMPLE SMOOTHIE CONFIG:

Paste this file onto your Smoothie SD card and reset your smoothie |

| ||||||

| comapact_head_v252.f3z (fusion archive file - recommended) | |

| File Size: | 89311 kb |

| File Type: | f3z |

| comapact_head_v252.step (no joints etc.) | |

| File Size: | 6905 kb |

| File Type: | step |

| Camera and Top plate drawing | |

| File Size: | 315 kb |

| File Type: | |

The example config above is setup to use this, the main difference is that instead of extruders for the nozzles (E0 and E1), this firmware uses A and B rotational axis.

- QTY 1 NEMA 17 REF ( 17HS1011-20B)

- QTY 2 NEMA 8 REF (HS-Nema8-5mm Shaft)

- QTY 2 9 x 75 linear rail REF (SS_MGN9-75)

- QTY 1 5v inductive sensor REF (DC5V-LJ8A3-2-Z/BX)

- HARDWARE ( I will be asking Robotdigg to make a hardware kit for the head, stand by):

M3 nuts QTY 4 REF

M3x8 QTY 34 REF

M3x20 QTY 4 REF

M2x8 QTY 8 REF

Delrin pins QTY 2 REF (3x16)