- Store

- >

- Pick and Place (PnP)

- >

- Pick and Place machined X and Y motion plates

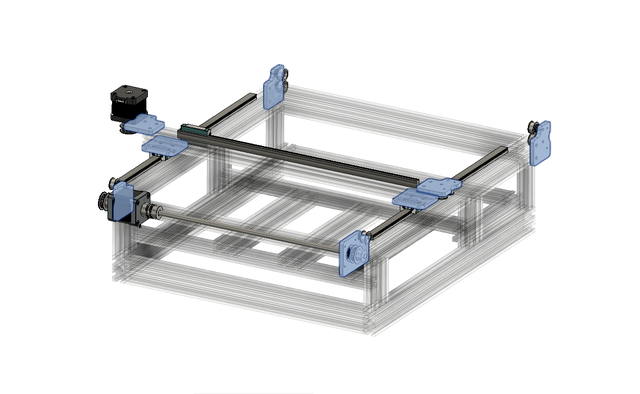

Pick and Place machined X and Y motion plates

SKU:

$85.00

$85.00

Unavailable

per item

2021-05-06: New more compact design!

Machined from 1/4" 5052 aluminium.

Only a few left!

NEW DESIGN!! Completely backwards compatible with the old design as pictured and described below (and in the drawing). Updated drawing to follow.

Careful geometry corrections have been made to the original design to ensure the belt paths are perpendicular to the frame to ensure linear movement from stop to stop.

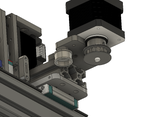

A full set includes two Y axis to X axis adapter plates to mount your gantry, 2 idler end plates (one for X and one for Y), 2 motor mount plates (one for X and one for Y, for NEMA 17 frame size) and 2 belt trap tensioner brackets (for the Y axis sled). Included as well by default is an extra idler plate, passive plate and 2 additional belt traps to drive the other Y rail. The passive plate has a bearing pocket for a 22mm (diameter) x 8mm (bore) x XX (height) flanged bearing to allow a 8mm smooth rod to link to the opposite Y drive system THE BEARING IS NOW SUPPLIED WITH THE KIT. NOTE: You will need a 5mm x 8mm shaft coupling to adapt the 5mm stepper shaft to the 8mm smooth rod driveshaft. Bearing example/ coupling example.

The design has tapped M5 mounting holes for the idler pulleys (Not included: 6 for passive, 9 for driven). Use a pulley like this one from Robotdigg. You will want to plan on spacing the idler pulleys referenced above about 6mm with M5 washers (1mm thick each) or a 6mm spacer.

Careful geometry corrections have been made to the original design to ensure the belt paths are perpendicular to the frame to ensure linear movement from stop to stop.

A full set includes two Y axis to X axis adapter plates to mount your gantry, 2 idler end plates (one for X and one for Y), 2 motor mount plates (one for X and one for Y, for NEMA 17 frame size) and 2 belt trap tensioner brackets (for the Y axis sled). Included as well by default is an extra idler plate, passive plate and 2 additional belt traps to drive the other Y rail. The passive plate has a bearing pocket for a 22mm (diameter) x 8mm (bore) x XX (height) flanged bearing to allow a 8mm smooth rod to link to the opposite Y drive system THE BEARING IS NOW SUPPLIED WITH THE KIT. NOTE: You will need a 5mm x 8mm shaft coupling to adapt the 5mm stepper shaft to the 8mm smooth rod driveshaft. Bearing example/ coupling example.

The design has tapped M5 mounting holes for the idler pulleys (Not included: 6 for passive, 9 for driven). Use a pulley like this one from Robotdigg. You will want to plan on spacing the idler pulleys referenced above about 6mm with M5 washers (1mm thick each) or a 6mm spacer.

Your browser does not support viewing this document. Click here to download the document.

ASSEMBLY:

Check out the parametric machine design assembly here to see how it all fits together, including a full BOM! The new machine design shows different motor plates but the current style will mount exactly the same if using dual Y motors.

DRAWINGS:

Here are some drawings with dimensions (you do not need any CAD software to view them):

NEMA17 motor plate:

a360.co/2PKZ40X

"sled" bracket (links the X rail to the Y rails):

a360.co/2CwaBPY

Idler plate:

a360.co/2PC2tPs

Belt trap/ tensioner:

a360.co/2Cl4oG8

Passive rail plate:

a360.co/2M4foYp

See our new reference machine design reference here.

HARDWARE (not supplied):

Check out the parametric machine design assembly here to see how it all fits together, including a full BOM! The new machine design shows different motor plates but the current style will mount exactly the same if using dual Y motors.

DRAWINGS:

Here are some drawings with dimensions (you do not need any CAD software to view them):

NEMA17 motor plate:

a360.co/2PKZ40X

"sled" bracket (links the X rail to the Y rails):

a360.co/2CwaBPY

Idler plate:

a360.co/2PC2tPs

Belt trap/ tensioner:

a360.co/2Cl4oG8

Passive rail plate:

a360.co/2M4foYp

See our new reference machine design reference here.

HARDWARE (not supplied):

- M3x6 (qty 8) for mounting the sled brackets to the Y rail bearing blocksM5x10 (qty 24, or 32 if driven passive rail) for mounting the plates to the extrusion (including the sled brackets)

- M3x14 (qty 4, or 8 for driven passive rail) for mounting the belt tensioner brackets to the sled brackets. Lengths of 12mm+ should be fine to allow for room to tension the belt

- M3x10 (qty 2, or 4 if driven passive rail) you can use anything similar to this as a pin for the belt to wrap around before going back out the tensioner bracket. See the pictures to make this more clear. In the pictures you can see one using an M3 screw and the other using a 1/8 steel pin.

Prices in US Dollars