- Store

- >

- Pick and Place (PnP)

- >

- Quick change Juki nozzle holders- NEMA8/ 11 hollow shaft

Quick change Juki nozzle holders- NEMA8/ 11 hollow shaft

SKU:

$49.00

$49.00

Unavailable

per item

2021-12-12: IN STOCK!!

(Link to open-source design files is at the bottom of this page)

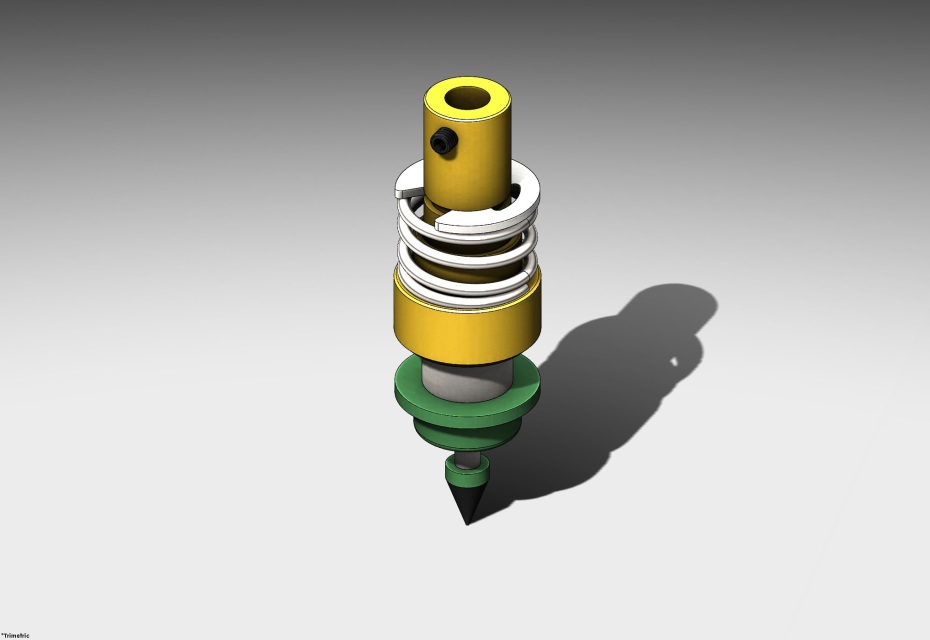

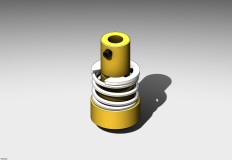

Pick and Place (PnP) machine Juki nozzle holders. These holders are Rev 2 of Mark Harris's licensed design and these are manufactured as a partnership between us.

This Nozzle holder is compatible with NEMA8 and NEMA11 hollow shaft stepper motors (with a 5mm shaft OD) and 500 series spring loaded Juki Nozzles.

This is V2 of Mark Harris's Juki Nozzle holder, some of the improvements include:

Shaft fit rather than press fit to the motor

Using a 0.0005” tolerance on the holes (previously 0.001”), we are moving to a shaft fit which should allow a motor shaft within tolerance to *just* slide onto the shaft. So both the bore size and tolerance have been improved.

This will be a tight fit, but will not require much force to seat. The advantage of this is that the brass will not be deformed as the shaft is pressed in, which will reduce run-out and improve concentricity. Those with slightly large motor shafts will now have a press fit, rather than a “I don’t know how this is every going to press on” fit. Those with slightly small motor shafts will still have a slightly loose shaft fit, the machinist recommends a drop of green thread lock to take up any slack and you will maintain run-out and concentricity. The collar still features a locking screw to ensure things won’t shift.

Improved ball retention

As part of optimizing the ball location, we changed the way that the balls are retained. This provides more surface area for the ball to seat against which in turn improves retention of the ball and its position. Previously we used two drill bits to create the feature that retained the ball, using the point angle of the second drill to create the retention face. We’ve now moved away from this.

Improved ball location

As mentioned above, we’ve improved the ball location to provide a better lock on the nozzle. It wasn’t really an issue before, but if things can be made better they should be!

Tighter tolerances

All tolerances have been reviewed in depth by the machinist. We now have 0.0005” tolerances for the features that sit against the motor shaft, and the tool holder. This does cost more, but improves accuracy. (+/-0.0005" tolerance on each side means that T.I.R. will be <0.001", typical is 0.0006" or better with the "clocking" method shown below).

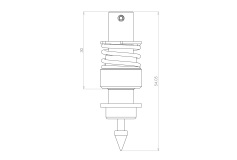

Length of holder itself: 30mm

Length of holder and Juki nozzle: 54.05mm (with 503 Nozzle)

These nozzle holders were developed with the openPnP community and are open-source for non-commercial use (meaning selling the nozzle holder for profit). You can find the design files here! (Give us some time to get the V2 design pushed through)

This is V2 of Mark Harris's Juki Nozzle holder, some of the improvements include:

Shaft fit rather than press fit to the motor

Using a 0.0005” tolerance on the holes (previously 0.001”), we are moving to a shaft fit which should allow a motor shaft within tolerance to *just* slide onto the shaft. So both the bore size and tolerance have been improved.

This will be a tight fit, but will not require much force to seat. The advantage of this is that the brass will not be deformed as the shaft is pressed in, which will reduce run-out and improve concentricity. Those with slightly large motor shafts will now have a press fit, rather than a “I don’t know how this is every going to press on” fit. Those with slightly small motor shafts will still have a slightly loose shaft fit, the machinist recommends a drop of green thread lock to take up any slack and you will maintain run-out and concentricity. The collar still features a locking screw to ensure things won’t shift.

Improved ball retention

As part of optimizing the ball location, we changed the way that the balls are retained. This provides more surface area for the ball to seat against which in turn improves retention of the ball and its position. Previously we used two drill bits to create the feature that retained the ball, using the point angle of the second drill to create the retention face. We’ve now moved away from this.

Improved ball location

As mentioned above, we’ve improved the ball location to provide a better lock on the nozzle. It wasn’t really an issue before, but if things can be made better they should be!

Tighter tolerances

All tolerances have been reviewed in depth by the machinist. We now have 0.0005” tolerances for the features that sit against the motor shaft, and the tool holder. This does cost more, but improves accuracy. (+/-0.0005" tolerance on each side means that T.I.R. will be <0.001", typical is 0.0006" or better with the "clocking" method shown below).

Length of holder itself: 30mm

Length of holder and Juki nozzle: 54.05mm (with 503 Nozzle)

These nozzle holders were developed with the openPnP community and are open-source for non-commercial use (meaning selling the nozzle holder for profit). You can find the design files here! (Give us some time to get the V2 design pushed through)

|

STEP 1: Verify NEMA8 shaft runout. In all motors we tested we were not able to detect any runout (remarkably).

|

STEP 2: Install nozzle holder on shaft and check runout. This video shows the worst case motor/ nozzle holder combination we could build in the shop for demonstration (0.0011").

|

|

|

|

|

STEP 3: If runout is excessive, experiment with "clocking" the nozzle holder on the NEMA8 shaft. Clocking means to rotate the nozzle holder slightly on the shaft and repeat runout checks.

|

Step 4: Install juki nozzle to visually verify measurements.

NOTE: In all possible motor/ nozzle holder combinations we have in the shop we were able to reduce runout to 0.00035" or better. Enjoy! |

Prices in US Dollars