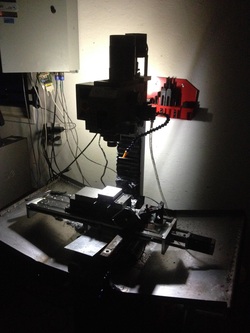

I decided to go ahead and install limit switches so I could do the TTS repeatable tool holders, probe and MSS (Mach Standard Mill) implementations at once. I am very sick of touching off after every tool change!! It was Taking me forever to come up with a design that I could machine on the mill, and then it hit me, 3D print them! I have make simple mounts for the TEMCO limit switches found here. X axis mount: This was the easiest because the adjustable stops were already on the cross slide. I also extended the bottom so that it would protect the Y axis lead screw that gets exposed.

4 Comments

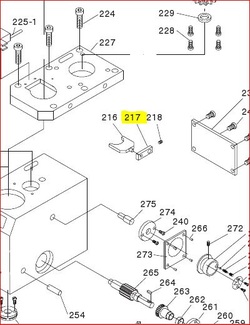

Seems I wasn't immune to having the plastic high/ low speed gear (p/n P0704212) strip on me. I crashed the mill in low gear cutting steel. It was hard enough to rotate the head about 20 degrees. Grizzly was good enough about supplying me one under warranty and I purchased an extra one for good measure. I believe I know a contributing factor to the gears stripping at least slightly before they should. I initially chalked it up to poor rigging as the low gear did not engage 100% of its tooth width. The more I looked at it however I realized there is no possible way to adjust the gear mesh quality and it does not engage 100% in low or high gear.  A possible solution would be to re manufacture the arm of the high/ low speed fork arm. If you were to make the fork arm p/n P0704217 a little longer than it currently is it would allow you to have more throw on either end of the travel, allowing the gears to mesh completely. Another option would be to make another detent plate (item 273 on the left) with the detents located further apart. I am not sure if something else limits the throw of the knob but I do not remember being able to rotate it past the detents. |

Author

Peter Betz Archives

April 2020

Categories

All

|

Prices in US Dollars

RSS Feed

RSS Feed