- Store

- >

- Pick and Place (PnP)

- >

- CP40 spring loaded nozzle holder for NEMA 8 and NEMA 11 hollow shaft motors.

CP40 spring loaded nozzle holder for NEMA 8 and NEMA 11 hollow shaft motors.

SKU:

$59.00

$59.00

Unavailable

per item

2021-09-23: The special o-rings have finally shipped! We will be able to ship all backorders (and new orders) the week of Sept 27. Thank you for your patience!

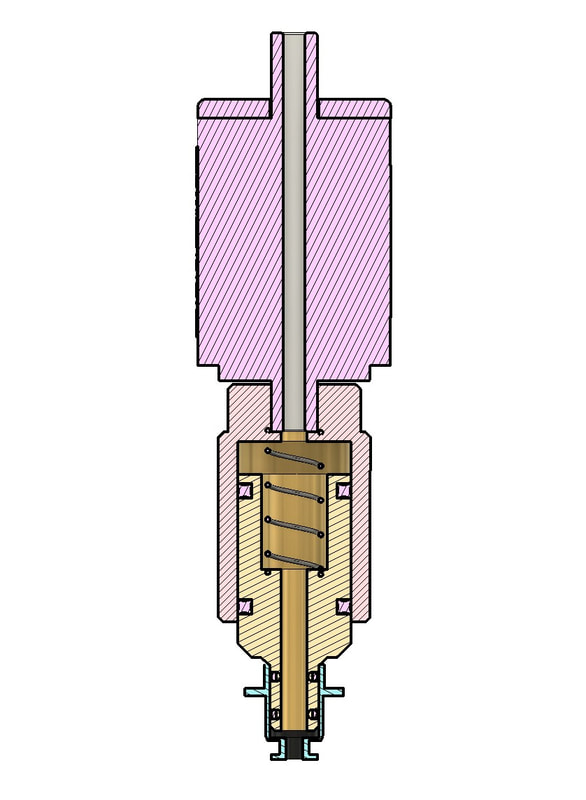

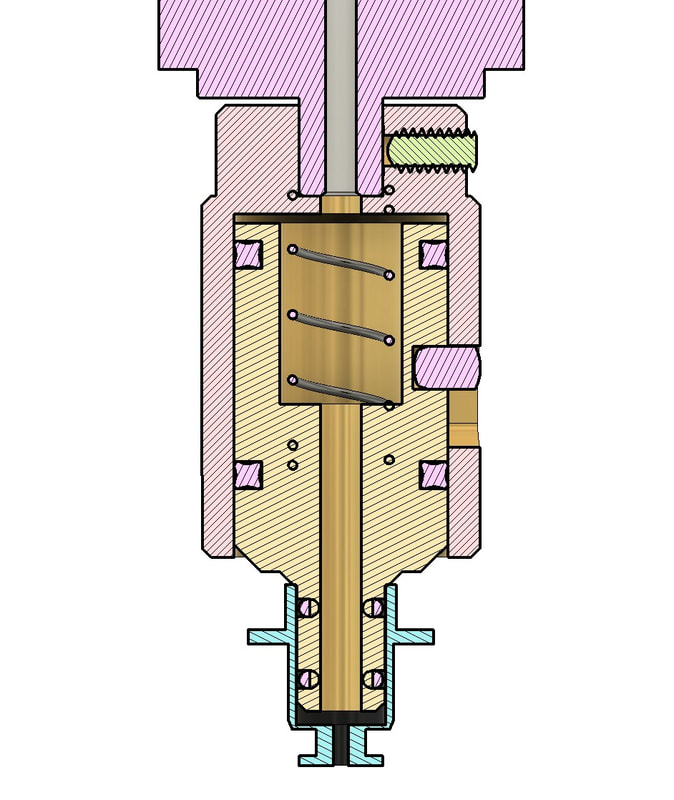

These holders were designed to take advantage of the high accuracy and low cost of the CP40 nozzle tips, while enjoying the benefit of the Z axis spring inside the holder (instead of inside each juki nozzle tip).

These holders were designed to take advantage of the high accuracy and low cost of the CP40 nozzle tips, while enjoying the benefit of the Z axis spring inside the holder (instead of inside each juki nozzle tip).

UPDATE: We have assembled and tested enough of these to have a better sense of their behavior. For our juki nozzle holder, we are able to guarantee a runout under 0.001" because the spring loaded sliding mechanism is in the nozzle itself, not the holder. There is a very wide range of juki nozzle quality out there and a lot of people report runout issues with the nozzle itself. This CP40 nozzle holder includes the sliding mechanism so it is very difficult to make any guarantees. What we can say is that in most cases, we can fiddle with the holder (trying different positions on the NEMA8 motor shaft, compressing and releasing the holder several times, etc.) and achieve a runout under 0.001", however it is possible that after compressing and releasing the holder again, you may see more runout. This is exactly similar to the Juki nozzle behavior. In most cases we do not see anything over 0.002" TIR at the CP40 nozzle tip, whereas it is very difficult to achieve this with the Juki nozzles themselves.

Advantages over the Juki Nozzle system: Easier automatic tool changes, reliance on one sliding mechanism instead of one in every nozzle tip, CP40 nozzles are easy to obtain and they all appear to be high quality and zero runout.

This design is also vacuum tight, as there a O-rings around the piston, and the nozzle tip is mounted with O-rings as well.

One of the main reasons why we designed this holder was to eliminate the high nozzle mounting pressure of other holders on the market (which require over 1,000g to insert the nozzle). We made this as low as possible, while still holding the nozzle onto the piston during rapid acceleration. Initial testing shows that the force required to slide the nozzle on to the piston does not exceed 40g.

The spring loaded piston requires about 250g to start compressing. the low nozzle insertion pressure means that automatic tip changing should be made significantly easier.

The holder also uses 3 precision dowel pins and 3 slots, to ensure that when the spring pushes out, the force is distributed evenly and allows the tip to remain centered.

Advantages over the Juki Nozzle system: Easier automatic tool changes, reliance on one sliding mechanism instead of one in every nozzle tip, CP40 nozzles are easy to obtain and they all appear to be high quality and zero runout.

This design is also vacuum tight, as there a O-rings around the piston, and the nozzle tip is mounted with O-rings as well.

One of the main reasons why we designed this holder was to eliminate the high nozzle mounting pressure of other holders on the market (which require over 1,000g to insert the nozzle). We made this as low as possible, while still holding the nozzle onto the piston during rapid acceleration. Initial testing shows that the force required to slide the nozzle on to the piston does not exceed 40g.

The spring loaded piston requires about 250g to start compressing. the low nozzle insertion pressure means that automatic tip changing should be made significantly easier.

The holder also uses 3 precision dowel pins and 3 slots, to ensure that when the spring pushes out, the force is distributed evenly and allows the tip to remain centered.

CAD MODEL DOWNLOAD

| cp40_holder_v15.step | |

| File Size: | 3877 kb |

| File Type: | step |

If you are looking to try these out on your machine that may already be equipped with our Juki nozzle holders, you should be aware of a couple things:

1: If you are using our head, the pins protrude slightly from the body of the nozzle holder so they will not slide though the bore in the NEMA 8 mounting plate. To assemble, you would remove the NEMA 8 motor from the plate, then slide the nozzle holder up from the bottom through the motor bore in the plate so that you can tighten the set screw onto the motor shaft (the nozzle holder will slide up until the pins hit the motor bore), then you can lower the motor onto the plate to secure it. (Any head kits sold with CP40 nozzle holders from now on will have these plates preinstalled on the motors and the runout of the nozzle holder verified).

2: The CP40 holders are 11mm shorter in length than the Juki nozzle holder (compared with nozzles installed). See the image below for a visual comparison:

Prices in US Dollars