- Store

- >

- Machine tool accessories

- >

- Accublast remote control CNC coolant nozzle

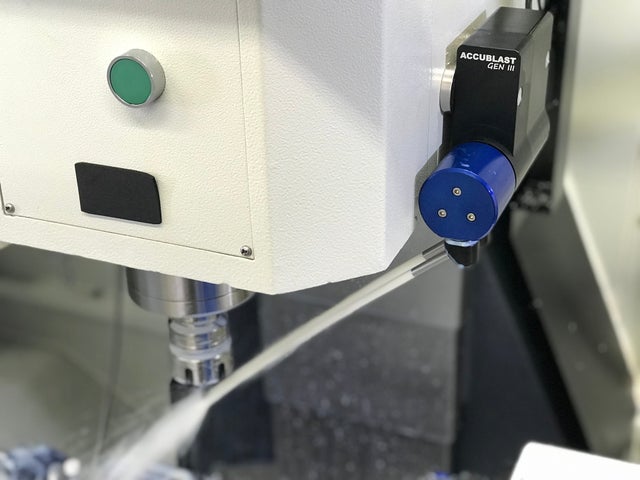

Accublast remote control CNC coolant nozzle

SKU:

$649.00

649

1449

$649.00 - $1,449.00

Unavailable

per item

PRO: Choose between SINGLE or DUAL [black and blue] servo units, with one or two turret jet nozzles [the black and chrome nozzles on the turret] for each.

2024-05-03: PLEASE NOTE THERE WILL BE AN APPROXIMATELY 2 WEEK LEAD TIME ON ACCUBLAST ORDERS.

Only a few left!

|

Now available as a factory option on Mazak Ez Series VMC's

All requests for sales/ support on Accublast coolant nozzles installed on Mazak Ez series machines must be directed to Mazak. Please contact your nearest Mazak representative for more information. www.mazakusa.com/offices-and-distributors/ |

Are you a Machine Tool Builder? Please email us to discuss offering the Accublast on your products!

-

About

-

Auto Mode

-

Getting Started

-

Downloads

-

Firmware

<

>

|

|

|

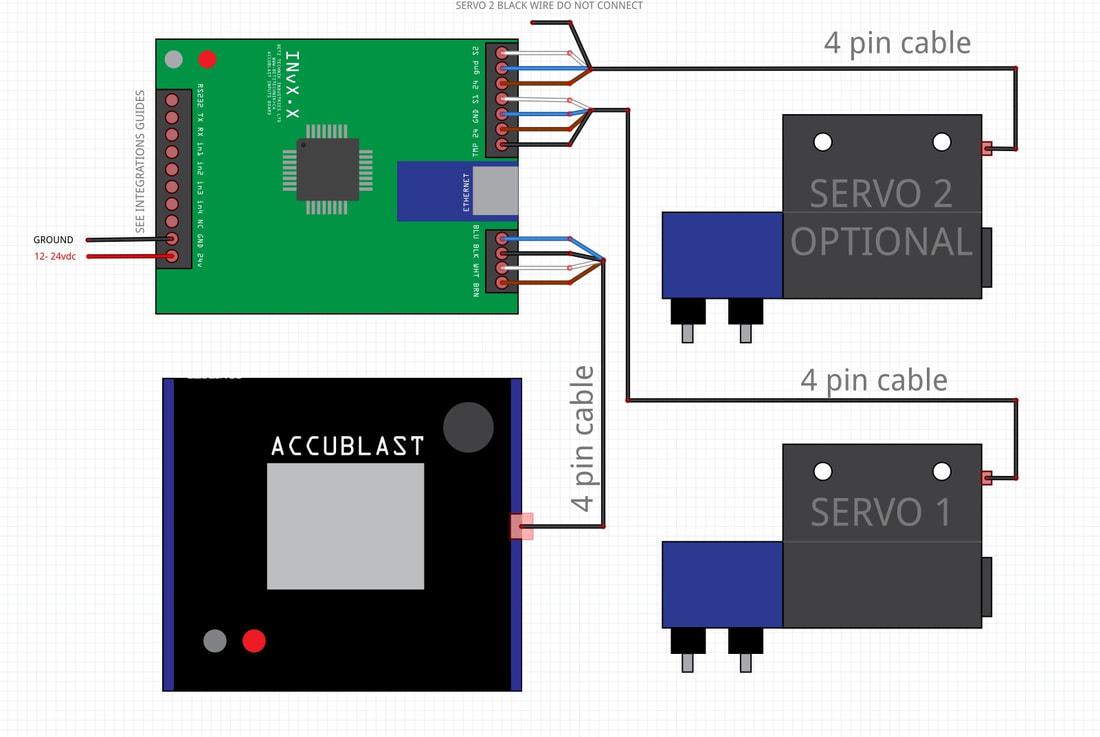

- Basic version all connections are made at the display (power, ground, servo unit connections).

- Basic supports pulse auto method.

- PRO version comes with an inputs unit to mount at the back of the machine to make all connections and uses a supplied 15' cable to connect the display unit for a clean installation.

- PRO version supports the following auto modes: Pulse, RS-232, umbrella ATC pin monitoring (index/ CW/ CCW pins).

- PRO Version allows 2 servo units to be connected and controlled from a single display.

The Accublast works very well as a simple, manual, remote control coolant nozzle. However it is also possible to synchronize the Accublast with your CNC machine so that it knows what tool is in the spindle, which is great for production work where an operator may not be tending to the machine continuously. To enable auto mode, these are the main methods (all of these auto modes are built in and selected from the display unit, meaning the Accublast can be ported to different machines without requiring programming or upgrades):

NOTE 1: You will require the "macros" option to be able to DPRNT on a HAAS either from RS-232 or Ethernet. You will NOT require the macros option for the Machine Data Collection method (Haas New Generation Control (NGC), Accublast ethernet option required).

- ATC PIN MONITORING: If you have an umbrella style ATC's where the tool goes back into the pocket they were pulled from, the Accublast can monitor the control wires to determine the position of the carousel and therefor the current tool number. In order to use this, you would want to look in the cabinet for three wires that are similar to these descriptions- (FWD or CW or Clockwise) (REV or CCW or Counter clockwise) (index or pulse). The index pin changes state when the each tool passes the spindle location, and the other wires control the carousel motor direction. (Confirmed integrations: LNC, Siemens 808D, FADAL)

- PULSE: This method requires a macro in the control that is called inside the tool change macro (typically M6). The macro will pulse an output wire high equal to the number of the tool. e.g. 5 pulses for tool high. The Accublast listens for a pulse and once it detects the first one it counts them until the timer expires (0.5s). The number it counted becomes the new tool number. (Confirmed integrations: Siemens 808D, Mitsubishi, FADAL with Calmotion control, Linux CNC, Suspect Linux CNC method will work with Tormach path pilot)

- RS-232: This method requires a macro in the control that is called from within the tool change macro (typically M6). The macro will "print" a serial message on the RS-232 port in the following format "T001" (tool number must be 3 digits!). Haas and Fanuc style "Dprnt()" commands should work well for this. NOTE 1.

- ETHERNET: Connect the Accublast to an Ethernet network to obtain the tool number. The Accublast can poll a machine data connection system (like Haas MDC) and the control will respond with the current tool number (this method requires no macro in the control!). You can also print messages to the Ethernet port on controls that allow it (Like Haas Dprnt over Ethernet, macro required). (Field testing complete for Haas DPRNT and MDC systems) NOTE 1.

NOTE 1: You will require the "macros" option to be able to DPRNT on a HAAS either from RS-232 or Ethernet. You will NOT require the macros option for the Machine Data Collection method (Haas New Generation Control (NGC), Accublast ethernet option required).

- A 12vdc 2A (min voltage) to 24vdc 1.5A (max voltage) power supply/ connection. If your machines power supply has additional capacity, you can use it to power the Accublast. You can also use a wall wart such as this one from Digikey.

- A 2.5A fuse or circuit breaker between the power supply and the Accublast.

- You will also need wire to supply the 12- 24v and GND to the unit. Use 18 AWG wire or larger.

- The back of the Accublast servo assembly has a female 3/8" NPT port. You will need a fitting to plumb the coolant to the nozzle. I use a 3/8" NPT x 1/2" push to connect fitting because I am using 3/8" ID tube. Here is an example.

- For Haas Ethernet units, you will need a router that supports DHCP, like the TP-link N300 if your machine is not already on a wired network. If it is on a wired network already, you may need to install an ethernet switch in the cabinet unless you can wire the inputs board to a port on your router. Contact us for more info

BASIC CONNECTION OVERVIEW

See user manual in downloads tab and integration information in the Auto Mode tab for more info.

|

|

|

3D MODEL:

|

Fusion 360 link: | ||||||

|

GEN III USER MANUAL:

|

| ||||||

Your browser does not support viewing this document. Click here to download the document.

|

GEN II USER

MANUAL: |

| ||||||

GEN I and GEN II2022-01-28 (v1.81):

2022-01-28 (v1.8):

2020-06-22 (v1.6):

2020-06-10 (v1.5):

2019-10-06 (v1.4):

2019-10-01 (v1.3):

|

GEN III2022-02-14 (v2.02):

2022-01-01 (v2.01):

|

GEN I and II firmware files only:

For GEN III firmware files and for GEN I and II instructions, click the programming link at the top of this tab

DISPLAY FIRMWARE

Make sure to update inputs and display boards together with the same version numbers!

Make sure to update inputs and display boards together with the same version numbers!

|

v1.81

|

|

v1.8

| ||||||

|

v1.7

| ||||||

|

v1.6

| ||||||

|

v1.5

| ||||||

|

v1.4

| ||||||

INPUTS BOX FIRMWARE

Only use metal box firmware if you have an ALUMINUM METAL INPUTS BOX!! Damage will result.

Only use metal box firmware if you have an ALUMINUM METAL INPUTS BOX!! Damage will result.

|

Pair with v1.81 display firmware

|

|

Pair with v1.8 above for METAL inputs box only

| ||||||

|

Pair with v1.7 above for METAL inputs box only

| ||||||

|

Pair with v1.6 above for METAL inputs box only

| ||||||

|

Pair with v1.5 above for PLASTIC inputs box

| ||||||

|

Pair with v1.4 above for PLASTIC inputs box

| ||||||

|

Pair with v1.4 above for METAL inputs box

| ||||||

Prices in US Dollars